The trigger sprayer is also called the hand button type, and it is also called the pistol type because of its shape. In terms of its working principle, it belongs to a pump sprayer. Widely used in household chemicals, car care products, pet supplies, gardening supplies, etc.

A brief introduction to the development history of the trigger sprayer

Patents for trigger sprayers appeared in the 1930s. There are some differences in shape and structural design, but the working principle is basically the same.

The domestic hand-operated sprayer was jointly developed in 1981 by Jiang Guomin, a senior engineer, and Wang Weizong, the former chief physician of Shanghai Sanitation and Epidemic Prevention Station.

In order to solve the leakage problem of the hand-pull spray, on the one hand, the sealing structure is improved, and then the heat-shrinkable film is used to seal the liquid material sprayer as a whole. Yn 1988, Mr. Jiang Guomin also developed an anti-leakage structure and designed a three-speed adjustable lever spray mister. The design structure is rotatable. Apply for a national patent.

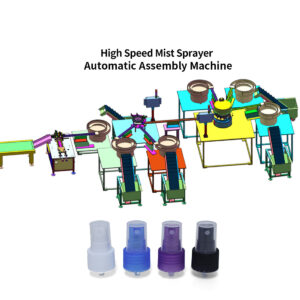

In the late 1980s, with the transformation of some domestic manufacturers, the market competition became increasingly fierce, but domestic product assembly still required manual production, which was very backward compared with foreign mechanized assembly.

At present, although some domestic manufacturers started late, they have advanced and scientific business concepts, and the company designs and manufactures molds by itself, and has designed and manufactured automatic assembly lines for sprayers and pumps, as well as quality inspection machines. As long as there are defective parts or other functionally unqualified products, they will be automatically rejected on the machine, achieving strict quality control and assurance.

Structural classification of trigger sprayer

The current market structure of sprayers is classified into trigger sprayers, multi-function trigger sprayers, large spray volume trigger sprayers, and dual-container quantitative mixing sprayers. The spray effect and spray volume of its products determine the distinction of different types of products.

Testing and Quality Control

Detection process classification:

(1) Incoming material inspection – including carton, plastic bag, glass beads, gasket, color masterbatch, raw material, spring, and other external parts inspection; Appearance, size, and function verification of each batch of incoming products; and record relevant inspection reports. Unqualified and issued unqualified inspection report for return processing.

(2) Injection molding process inspection – self-inspection of the production workshop in the process; according to product inspection instructions and inspection equipment; QC conducts appearance and functional class inspections every shift; product appearance inspections every 2 hours and record inspection reports; The first inspection record and the first inspection data report are carried out for the machine and the color matching mold.

(3) Inspection of the installation process – self-inspection of the production workshop during the process; according to customer standards, finished product inspection instructions and testing equipment; first inspection and inspection for each startup and line transfer; The number of pumps, ejection volume, total height, pipe length, etc. are detected and recorded.

(4) Finished product inspection – according to the standards provided by the customer; QC conducts sampling inspection after product packaging; product appearance and function inspection; product pumping times, pump output, straw length, etc.

(5) Delivery inspection – according to the customer’s standard, conduct appearance, and size inspection and record the COA report to provide customer reference confirmation together with delivery.