A pump is a mechanical device that releases the content in a predetermined form and has a sealing performance by pressing the principle of vacuum.

After decades of development, the pump has been in-depth into all aspects of daily life. And function, appearance, practicality are greatly improved, the following on the development of a variety of pumps and working principles, testing standards and so on to make some brief introduction.

History of pump development

There are available historical records, China as far as 500 years ago in 1449, has been in the widespread use of this kind of dispenser, when called “water dragon”.

“Water Dragon” is the old common name of the fire extinguisher: by a height, width of about 0.8 meters, about 1 meter of wooden barrels, a number of sub-buckets, with a water belt, nozzle, and other facilities. Install a well-shaped wooden mat at the bottom of the bucket to keep the water running smoothly. Two copper-cast pumps are placed side by side in a large wooden bucket. One of the Pistons moves up and down. The pistons are connected to the upper lever and press the lever, the water will be ready to shoot out. The two walls around the bucket wall are each equipped with a movable iron ring handle, which is convenient for two people to carry the water dragon when rescuing the water. The other two people use one hand to carry the handle to assist to lighten the load of the person carrying the water dragon and speeding up the speed of running to save the water time.

The comparison of the development of modern history between China and foreign countries is also reflected in the development of dispensers. Industrial production and consumer demand, bringing Europe and the United States in the distributor of the booming development. One of the first things that came up was valves.

The concept of 1790 originated in France with the introduction of a pressurized carbonated beverage.

In 1837, An aerosol bottle filled with soda water was invented by a man named Perpignan.

In 1899, The first aerosol canisters using methyl and ethyl chloride as propellants were patented by inventors Helbling and Pertsch.

The Cosmetics giant L ‘Oreal invented the Lotion in 1930. But there was no emulsion pump so convenient to use the device, the common use of lids.

In 1966, an eighth-grader in Quebec, Canada, invented our original emulsion pump using a ballpoint pen and tubes during a science experiment.

In 1996, a company in Europe and the United States caused water problems because of the design defects of the emulsion pump head used in baby products, and thus constitute a lawsuit, three companies around the world to invent the anti-entry pump head leading the trend for decades. Emulsion pump head into a new era.

In 2013, a Chinese manufacturer responded to the new market demand of Unilever, the giant daily chemical company, and launched the world’s first emulsion pump specially used for e-commerce channels.

History of international development

| Aptar | Founded in 1940. |

| Coster | Founded in 1963. |

| WestRock(Calmar) | Founded in 1969, the first Shower Guard inlet pump was introduced in 1997. |

| Albea | Buy Rexam in 2010. |

History of Asian development

Japan

| Toyo Seikan | Founded in 1917. |

| Yoshino | Founded in 1935,1997 launched the first generation of waterproof pumps. |

| Daiwa Can | Founded in 1936, the first vacuum tank design was sold to air spray in the Netherlands |

| Mitani | Founded in 1956. |

| Canyon | In 1958 the first plant in South Korea, followed by the birth of a large number of Korean manufacturers. |

South Korea

| Apollo | Founded in 1976. |

| Yonwoo | Founded in 1983. |

| Chongwoo | Seaquist agency was established in 1992. |

| Darin | Founded in 1993. |

China

| Sunrise | The first 3.5 ml emulsion pump was introduced in 1979. |

| TKK | 1976 acting Europe and the United States all kinds of allocator. |

| JM | Founded in 1987. |

| TKPC | In 1992, TKK began to set up factories on the mainland and developed the simplest WaterShield first-generation intake pump. |

| ZZ | Founded in 1992. |

| CLC | Founded in 1994. |

| Majesty | Founded in 2001. |

| Songmile | Founded in 2005. |

Working principle of emulsion pump

When the first press down the ACTUATOR, the BALL valve (BALL) and the body (HOUSING) are closed, and the sealed gas in the body is forced out from the SUB-STEM hole through the head mouth;

When the PISTON springs up, the PISTON is sealed with the auxiliary column, and rises under the action of the SPRING, causing the body to form a sub-vacuum state and produce suction, will make the liquid through a TUBE (DIP TUBE), ball valve, and into the body;

When pressing down again, the ball valve and the body closed, the body of the liquid extrusion, will be forced from the vice-column hole through the head by mouth and discharge!

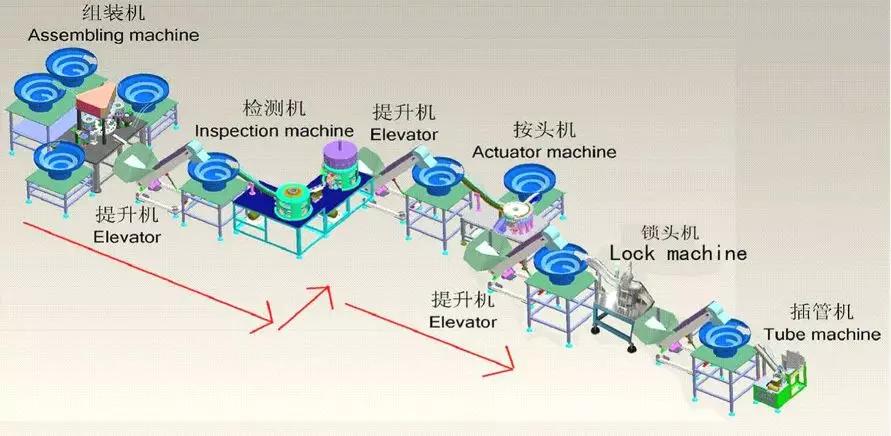

The manufacturing process– the manufacturing process flow diagram

| 01 | Raw materials. |

| 02 | Check. |

| 03 | put in storage. |

| 04 | Mixed material. |

| 05 | Injection molding. |

| 06 | measure and test. |

| 07 | put in storage. |

| 08 | Oil shaking. |

| 09 | Piston machine. |

| 10 | Assembling machine. |

| 11 | Detector machine. |

| 12 | Actuator machine. |

| 13 | Lock machine. |

| 14 | Tube machine. |

| 15 | Final test. |

| 16 | Automatic Baler. |

| 17 | put in storage. |

| 18 | Shipping out. |

Testing and quality control

01. Sealing: fill the bottle with colored water (or customer’s liquid) according to the product specification, use the corresponding torque to make the pump head match with the bottle according to the different caliber, vacuum Test-0.03 ~-0.06 MPA/5 min (different customer requirements are not consistent). After testing, there is no leakage between the bottle and the screw thread, between the body and the locking cap, according to the head part.

02. According to the head with the main column, according to the head and the main column of the separation force should be able to withstand the weight of the whole package. General parameters can not be less than 2Kgf for eligibility.

03. Air pressure times/first injection times. Refers to the number of times the consumer presses the head from the opening of the head to the first discharge of the liquid. The common standard is 6 ~ 10 times.

04. Pump output: refers to the consumer each time the use of emulsion pump, pump out the volume of liquid. The normal tolerance of the pump output is about ± 10% of the theoretical design value.

05. The opening torque between the head and the lock cover is 3-10kgf cm.

06. Drop test: along with side the corresponding bottle, fill the standard weight of liquid (or water), to the height of 0.8 ~ 1.2 meters vertical drop cement ground once, bottle first landing, the product is not broken and loose to pass. (note: This test will only be performed if the material is changed or the formula changed, or if the new mold is first mass-produced.).

07. Pressure pump feels: good rebound, no hysteresis, rebound time ≤1.5 seconds, fatigue test compression ≥2000 times, the rebound should be normal.

08. Straw with the body to moderate tightness, not too loose (easy to fall off) or too tight (easy to make the body burst). General parameters can be not less than 0.5 kg for qualified (different hose specifications of products need to be re-evaluated).

09. Screw and bottle mouth with smooth, no sliding teeth and block, skew phenomenon.

Use case analysis and prospects

Lotion pump products are widely used in beauty and washing products and other daily chemicals, cosmetics, and pharmaceutical packaging, its main characteristics are simple structure, stable function, ease to use, environmental protection, high quality and cheap, widely used, huge market potential and demand.

The packaging industry of daily chemical products is also developing into a new industry with continuous technical progress, increasing added value, and more considerable scale!