Ana kuma kiran mai fesa mai faɗa da nau'in maɓallin hannu, kuma ana kiranta da nau'in bindiga saboda siffarta. Dangane da tsarin aikin sa, na mai fesa famfo ne. Ana amfani dashi sosai a cikin sinadarai na gida, kayayyakin kula da mota, kayan dabbobi, kayan aikin lambu, da dai sauransu.

Takaitaccen gabatarwa ga tarihin ci gaba na mai faɗakarwa

Halayen haƙƙin mallaka don masu fesa masu jawo sun bayyana a cikin 1930s. Akwai wasu bambance-bambance a cikin tsari da tsari, amma ka'idar aiki iri ɗaya ce.

An samar da injin feshin hannu tare a cikin gida 1981 da Jiang Guomin, babban injiniya, da Wang Weizong, tsohon babban likita na Shanghai Tsaftar Tsaftar da Annoba ta tashar.

Domin magance matsalar zubewar feshin-jawo da hannu, a gefe guda, an inganta tsarin rufewa, sannan a yi amfani da fim ɗin da za a iya rage zafi don rufe abin fesa ruwa gaba ɗaya. A ciki 1988, Mr. Jiang Guomin kuma ya ƙirƙiri wani tsari na hana yaɗuwar ruwa kuma ya ƙirƙira injin feshin lefa mai saurin sauri uku.. Tsarin zane yana juyawa. Aiwatar don haƙƙin mallaka na ƙasa.

A karshen shekarun 1980, tare da sauyi na wasu masana'antun cikin gida, gasar kasuwa ta kara tsananta, amma har yanzu taron samfuran cikin gida yana buƙatar samarwa da hannu, wanda ya kasance koma baya sosai idan aka kwatanta da taron injiniyoyi na waje.

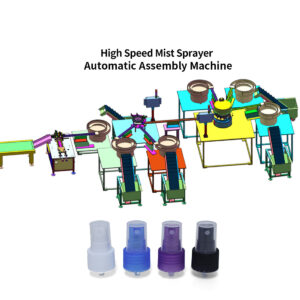

A halin yanzu, kodayake wasu masana'antun cikin gida sun fara a makare, suna da ci-gaba da dabarun kasuwanci na kimiyya, kuma kamfanin yana tsarawa da ƙera ƙira da kansa, kuma ya ƙera kuma ya ƙera layukan taro na atomatik don masu feshi da famfo, da kuma ingantattun injunan bincike. Muddin akwai ɓangarorin ɓarna ko wasu samfuran da basu cancanta ba, za a ƙi su ta atomatik akan injin, samun ingantaccen kulawa da tabbatarwa.

Rarrabe tsarin na mai fesa

Tsarin kasuwa na yanzu na masu feshi an rarraba shi cikin masu feshi masu jawo, Multi-aiki jawo sprayers, manyan feshi girma jawo sprayers, da na'urori masu juzu'i na kwantena biyu. Tasirin fesa da ƙarar feshin samfuran sa yana ƙayyade bambancin nau'ikan samfuran.

Gwaji da Kula da Inganci

Rarraba tsarin ganowa:

(1) Duban abu mai shigowa – ciki harda kwali, jakar filastik, gilashin beads, gasket, launi masterbatch, albarkatun kasa, bazara, da sauran sassan dubawa na waje; Bayyanar, girman, da kuma tabbatar da aiki na kowane rukunin samfuran masu shigowa; da kuma rubuta rahotannin dubawa masu dacewa. Rashin cancanta da bayar da rahoton dubawa mara cancanta don sarrafa dawowa.

(2) Duban tsarin gyaran allura – duba kai na samar da bitar a cikin tsari; bisa ga umarnin duba samfur da kayan dubawa; QC tana gudanar da duban gani da aikin aji kowane motsi; dubar bayyanar samfur kowane 2 sa'o'i da rikodin rahotannin dubawa; Rikodin dubawa na farko da rahoton bayanan dubawa na farko ana aiwatar da su don injin da kuma ƙirar da ta dace da launi.

(3) Binciken tsarin shigarwa – duba kai na bitar samarwa yayin aiwatarwa; bisa ga matsayin abokin ciniki, gama umarnin duba samfurin da kayan gwaji; dubawa na farko da dubawa don kowane farawa da canja wurin layi; Yawan famfo, ƙarar fitarwa, tsayin duka, tsawon bututu, da dai sauransu. ana gano kuma an rubuta su.

(4) Kammala binciken samfurin – bisa ga ka'idojin da abokin ciniki ya bayar; QC tana gudanar da binciken samfurin bayan fakitin samfur; bayyanar samfurin da duba aikin; lokutan yin famfo samfur, fitar da famfo, tsayin bambaro, da dai sauransu.

(5) Duban isarwa – bisa ga ma'auni na abokin ciniki, gudanar da bayyanar, da girman dubawa da yin rikodin rahoton COA don samar da tabbaci na abokin ciniki tare da bayarwa.