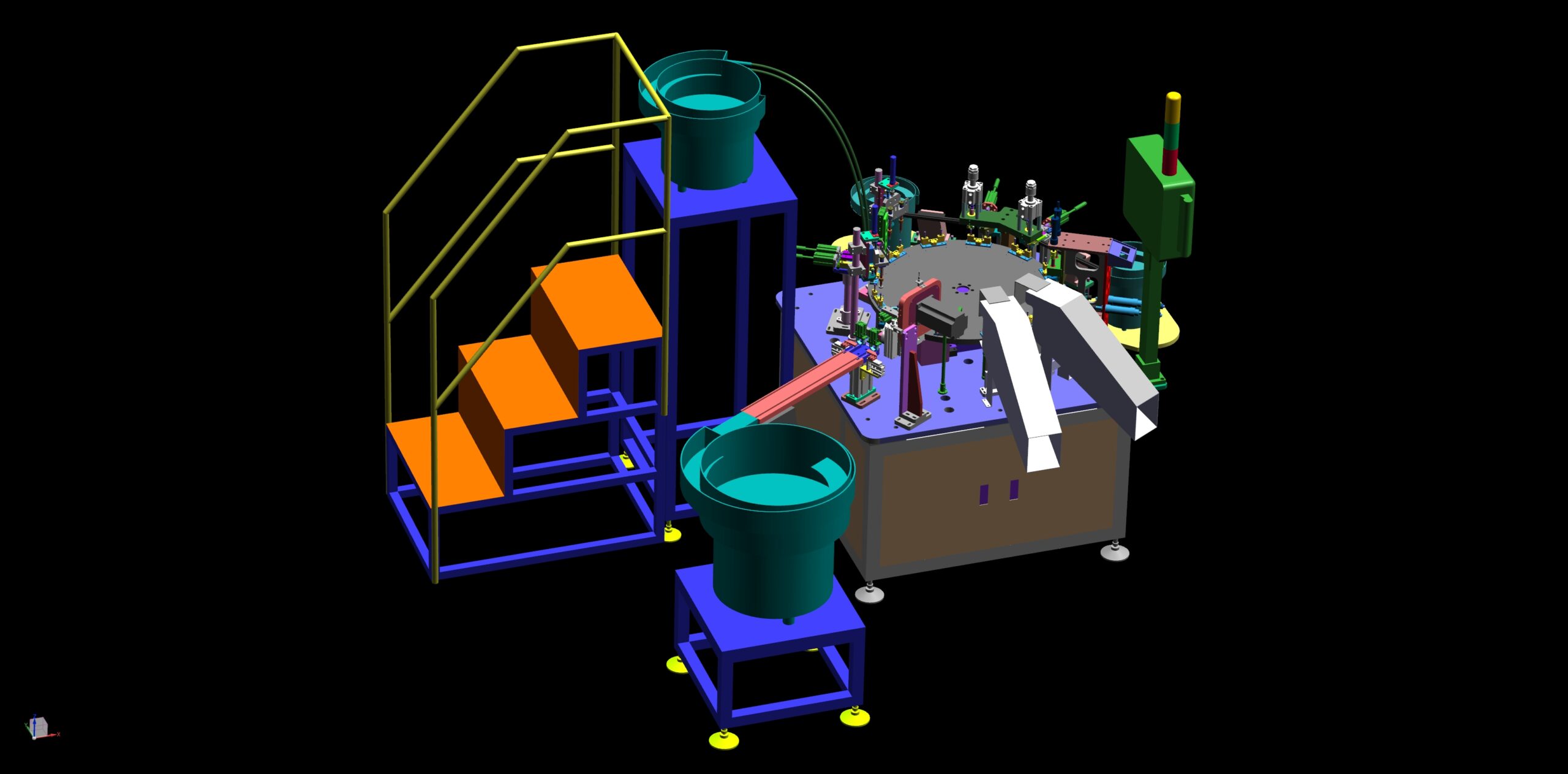

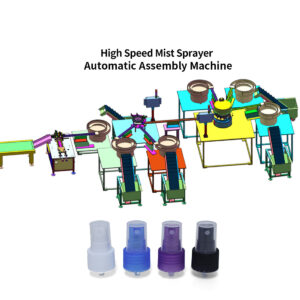

The nasal spray compass accessories are transported to the vibration plate through a hoist

The vibrating disk orderly passes the compass through the conveyor belt

Enter the rotary table machine and insert the pump core

Insert the pump core on one side of the rotary table machine and press on the nose nozzle cap on the other side

Customized straw length according to customers

Machine cutting, inserting nasal spray

A complete nasal spray is assembled

Through quality sorting, packed in dustproof bags for packaging

Stable operation, fast speed, low noise, and high accuracy

The yield rate can reach 99.9%