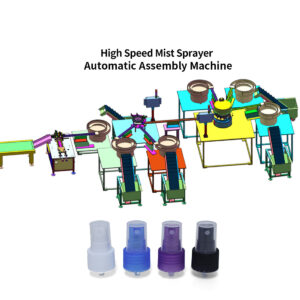

Kami bukan sahaja mengeluarkan barangan pembungkusan plastik, tetapi kami juga mereka bentuk dan mengeluarkan mesin pembuatan pembungkusan plastik. Currently, the company primarily develops and manufactures automatic assembly equipment for everyday chemical items such as plastic square guns, pam losyen, tiny sprays, dan sebagainya. Jentera beroperasi. Stabil, pantas, bunyi rendah, ketepatan yang sangat baik, dengan 99.9% kadar hasil. Ia cekap dan stabil, mudah digunakan dan diselenggara, dan menggabungkan pemasangan dan ujian. Reka bentuk tersuai boleh dijalankan untuk memuaskan hati pelanggan’ keperluan pemasangan untuk pelbagai produk dan mengurangkan bilangan kakitangan pemasangan untuk pelanggan. Ia juga mengurangkan kos pengeluaran produk dengan ketara, membolehkan pelanggan meningkatkan margin keuntungan dan potensi pasaran.

An automated assembly machine is a type of efficient mechanical equipment that uses numerous sensors, actuators, and control systems to realize automatic product assembly through programming and automation technology. The use of automated assembly machines in modern production is becoming increasingly common, offering significant benefits and improvements.

The functions and tasks of the automated assembly machine are as follows:

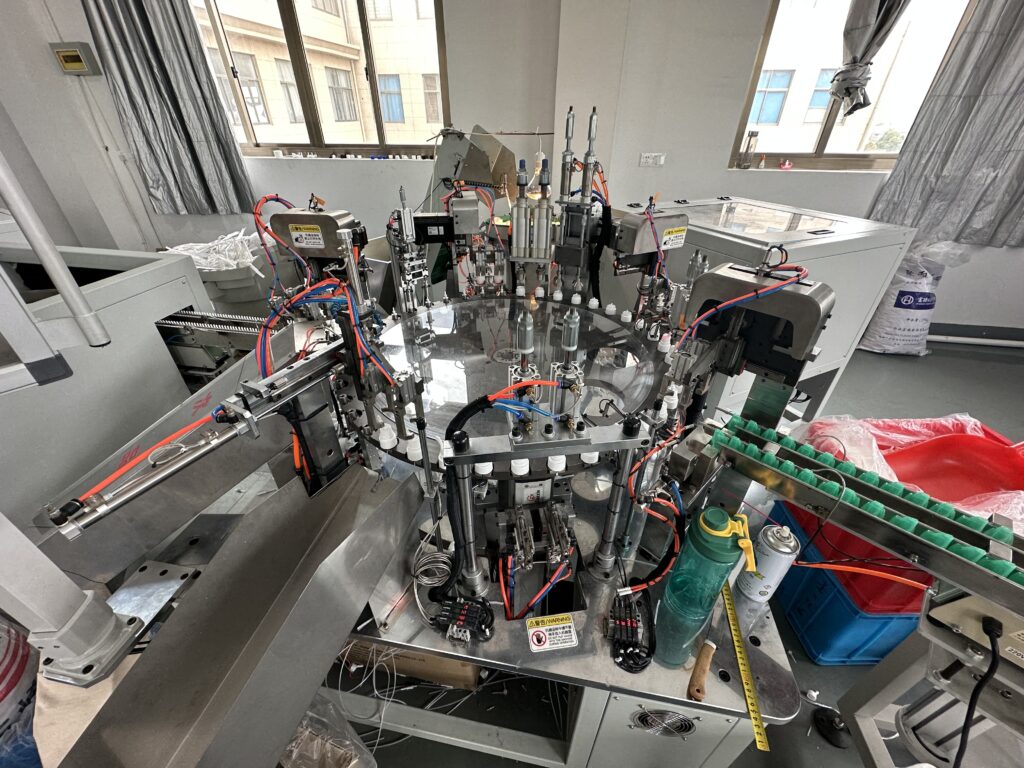

1.Conveyor system is in charge of moving products from one workstation to the next. To achieve high-speed and precision product transfer, the transmission system often employs conveyor belts, rails, or robotic arms.

2.A product identification system is used to identify its attributes and location. The identification system identifies the logo or features on the product using image processing, photoelectric sensors, or barcode scanning for subsequent processing and assembly.

3.The clamping and assembling system is the assembly machine’s heart. It is in charge of putting together various pieces to make the final result. Clamping and assembling systems typically contain robotic arms, fixtures, and tools, among other components, that assemble parts to specific positions step by step using precise position control and force adjustment.

4.The control system is the assembly machine’s brain, and it is in charge of controlling the complete assembly machine’s functioning. PLC (programmable logic controller) or computer-based control systems can be programmed and operated. It can monitor the operational state of each item in real time and automatically change and control it based on the parameters and rules defined to ensure the assembly’s correctness and stability.

5.During the assembly process, the data recording and analysis system collects and analyzes data. The data recording and analysis system may record various parameters and indications during the operation of the assembly machine, such as temperature, pressure, speed, dan sebagainya, using sensors and monitoring equipment. These data can be utilized to optimize and improve the manufacturing process, hence increasing production efficiency and quality.

Advantages and application value of automated assembly machines:

For starters, it has the potential to dramatically lower labor expenses. Mesin pemasangan automatik, when compared to traditional manual assembly, may achieve high-speed and efficient output while reducing manual procedures and personnel requirements.

Second, automated assembly machines have the potential to improve product consistency and quality. Because of the machine’s exact positioning and control capabilities, each product can be assembled to the same standards, reducing errors caused by manual procedures.

Third, automated assembly machines can boost production flexibility and scalability. Automated assembly machines can adapt to the assembly needs of different goods by programming and configuring multiple process flows, and they can readily alter and improve the process.

Application areas of automated assembly machines:

Automated assembly machines are used in a variety of industries, including electrical items, vehicle parts, and household appliances. Automated assembly machines in the electronics industry may assemble and connect circuit boards, improving manufacturing efficiency and product stability. In the automotive sector, automated assembly machines can perform part assembly and assembly, increasing production speed and quality. Automated assembly machines in the domestic appliance industry can accomplish assembly and debugging of household appliances while improving product consistency and quality.

In conclusion, an automated assembly machine is a highly efficient and intelligent equipment that can provide significant production benefits and adjustments. Through programming and automation technologies, it achieves high-speed, high-quality product assembly by utilizing modern sensors, actuators, and control systems. With the continuing improvement of science and technology, the use of automated assembly machines will become more common, bringing new opportunities and difficulties to the manufacturing industry’s development.

We adhere to the quality first and service first principle, and endeavor to attain the finest product quality and service while remaining realistic, enterprising, and pushing for greatness.