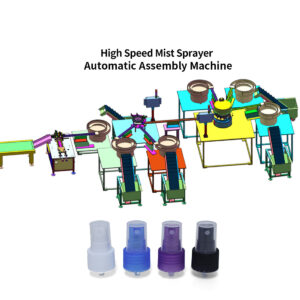

The following procedures are commonly involved in the automated assembly of plastic emulsion pumps.

Silo supply is the transfer of individual plastic components from a silo to a conveyor belt, such as a pump body, pump cover, piston, e te tahi atu â. A vibratory tray can be used to automate this process. This can be automated using vibratory discs, feeding robots, and other devices.

Assembly Station – On the conveyor belt, components such as pump bodies, pump covers, pistons, and so on enter the automatic assembly station. The assembly station performs positioning and assembly using manipulators, assembly fixtures, and other tools. The assembly procedure can be carried out by manipulators picking up individual components for assembly or by components being automatically conveyed to the assembly station by the conveyor.

Inspection Station – The assembled pump enters the inspection station, where sensors and inspection equipment inspect the assembly’s quality. Sensors inspect the assembly’s quality, such as the fit of the pump body to the pump cover, the sealing of the piston to the pump body, e te tahi atu â.

Pumps that pass the quality inspection are automatically marked with a serial number and then transferred to the automatic packing station for packaging. Pumps that are not qualified will be marked as defective and removed.

Finished Product Output – Finished packaged products that are ready for storage or shipment are automatically output via conveyor belt.

Te tereraa taatoa o te tairururaa ma te faaohipa i te hoê matini uira, Te mau nota, e te hoê faanahoraa PLC no te faatupu i te ohipa e te hi'opo'araa maitai ma te ore e titau i te tautururaa a te taata, Te mau mana'o tauturu no te haapiiraa e te avatea mahana maa. No te tapea i te tereraa mǎrû o te tairururaa, e mea ti'a atoa ia tatou ia hi'opo'a i te faanahoraa o te maa, te atuaturaa i te mau tauihaa, Mana'o Tauturu i te Haapiiraa, e te tahi atu tautururaa.